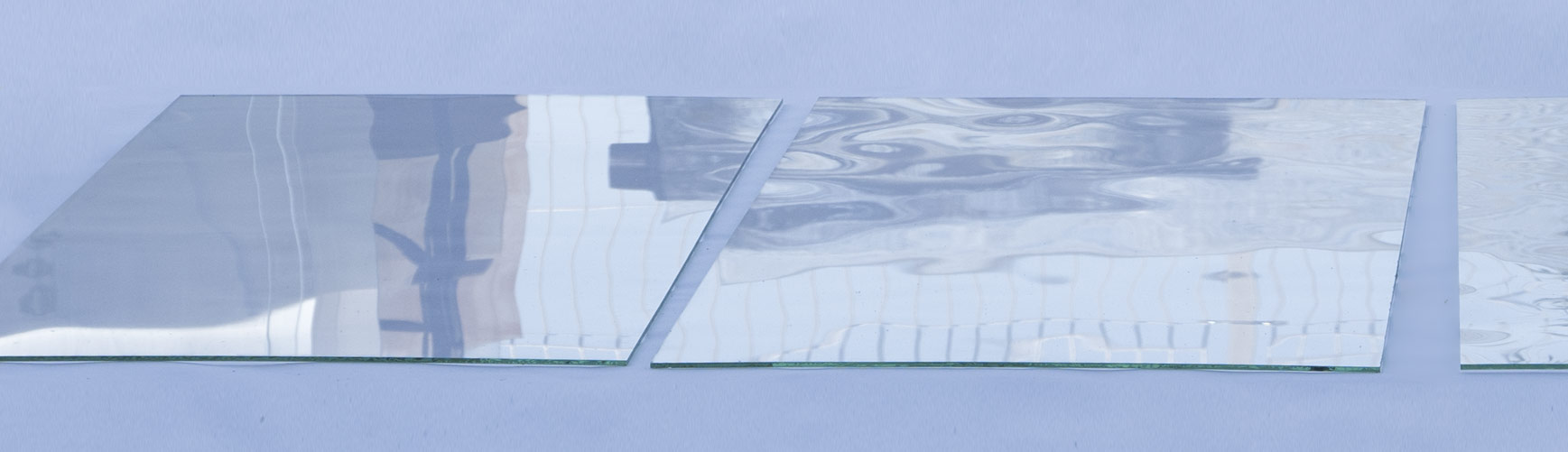

Producing of the restoration glass

We produce restoration window glass which is an equivalent of drawn glass - a product made according to Fourcaults' or Pittsburgh technology.

This type of glass is used for various applications - architecture, old clocks, carriages, etc. Glass sheets are available in every shape, dimension, and thickness. We manufacture this type of glass for the restoration of buildings and for needs of the companies specializing in monument conservation. It is used when the "old glass" appearance is needed. As the contemporary float glass perfection doesn't suit the historical buildings, there is a need to use "uneven" and slightly waved sheets of restoration glass.

Up to the mid-twentieth century window glass was produced in the Drawn Sheet technique - a "ribbon" shaped, long sheets were pulled up continuously, cooled, and eventually cut into smaller parts. Small temperature changes during the hardening were causing some thickness variations and lines of slight distortions. Since 1950 window glass is produced by the float glass process in which molten glass is spread along a tin bath. The finished product has a perfectly smooth surface. Nowadays it's the most popular type of glass for architectural use. Due to its neatness and lucidity, it fits modern architecture.

However in monumental, historical buildings this neatness can be jarring. In the restoration process, it's important to keep an authentic look.

Imperfect but charming restoration glass will help maintain the unique atmosphere of the times and fulfill the conservation requirements.

PARAMETERS AND PROPERTIES OF THE RESTORATION GLASS - Custom-made for historical architecture and lofts.

Maximum dimensions of restoration glass sheet: 140 cm (55,1 inches) x 250 cm (98,4 inches). The thickness of restoration glass depends on the size of the sheet (and the larger the glass, the thicker the glass should be). Different degrees of distortion. It is possible to vary the structure of glass depending on individual requirements. AN IMPORTANT NOTICE: Delicate smoked-like effects on some parts of the sheets and traces of contact between the glass and the floor of the kiln during the heat treatment process may be visible on the glass surface. These features are characteristic of this type of glass and give to it the character of manual production.